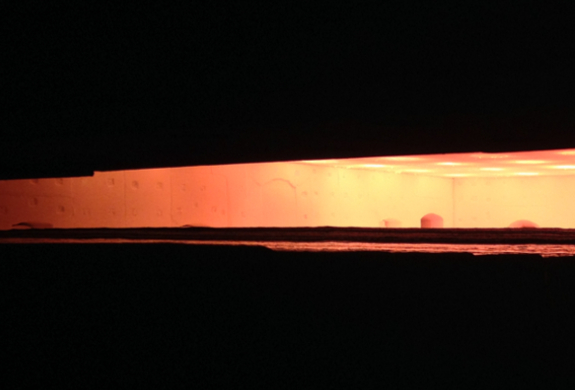

Pusher type top fired

forni a spinta riscaldati dall'alto

This kind of furnace represent the more simple and economic solution to be adopted on a rolling mill. Generally they are used for rounds, wire, rebars. Billets are placed adjacent one to the other and pushed inside by means of hydraulic pushers, only by front. Heating is obtained by burners , placed on roof ( radiant or flat shape flame) or on front and walls. Billets are charged by front and discharged by front or by side.

Oltre a costruire bruciatori Ultra Low NOx emission, vogliamo offrire al mondo della laminazione, della forgia e del trattamento termico, con uno sguardo al settore dell’Alluminio, la possibilità di avvalersi della nostra consulenza per pianificare, progettare e realizzare impianti di riscaldo ad elevata efficienza e o procedere a revamping per ridurre i costi di trasformazione e limitare le emissioni in atmosfera. I principali campi d’azione possono essere sintetizzati in:

Oltre a costruire bruciatori Ultra Low NOx emission, vogliamo offrire al mondo della laminazione, della forgia e del trattamento termico, con uno sguardo al settore dell’Alluminio, la possibilità di avvalersi della nostra consulenza per pianificare, progettare e realizzare impianti di riscaldo ad elevata efficienza e o procedere a revamping per ridurre i costi di trasformazione e limitare le emissioni in atmosfera. I principali campi d’azione possono essere sintetizzati in:

In addition to building Ultra Low NOx emission burners, we want to offer to the rolling, forging and heat treatment fields, with a look at the aluminum industry, our consulting to plan, design and build high temperature heating systems really efficient and eventual existing furnace’s revamping to reduce production costs and to control pollution limit emissions to the atmosphere. The main areas of action can be summarized in:

In addition to building Ultra Low NOx emission burners, we want to offer to the rolling, forging and heat treatment fields, with a look at the aluminum industry, our consulting to plan, design and build high temperature heating systems really efficient and eventual existing furnace’s revamping to reduce production costs and to control pollution limit emissions to the atmosphere. The main areas of action can be summarized in: